I’ve decided that I need a new XY gantry. The old one is fine, if you don’t want to change nozzles. As this is a very basic requirement of this project, I’ve had to come up with a solution to a mechanical problem I have while changing nozzles with the old gantry and carriage.

The Old Gantry

As I said before, the old gantry is fine, if you don’t want to change nozzles. The thing is, the particular nozzle holder that I have has a tiny tolerance. It has to. Otherwise, the negative pressure created by the vacuum pump, would be lost.

So, here we go down the rabbit hole. Bear with me, this is a work in progress, and there will be more to come.

The problem that I’ve run into, is that the NEMA8 motor is sitting relatively far away from the aluminium rods, so pushing up on the nozzle holder has a significant amount of leverage. The aluminum rods themselves aren’t that strong, certainly not when force is applied to them. When I try to put in a nozzle, the whole carriage bends upwards, creating an angle between the nozzle holder, and the nozzle. This causes binding, and naturally skipping of Z steps when it can’t get the nozzle in. The same applies for removing a nozzle, just in reverse.

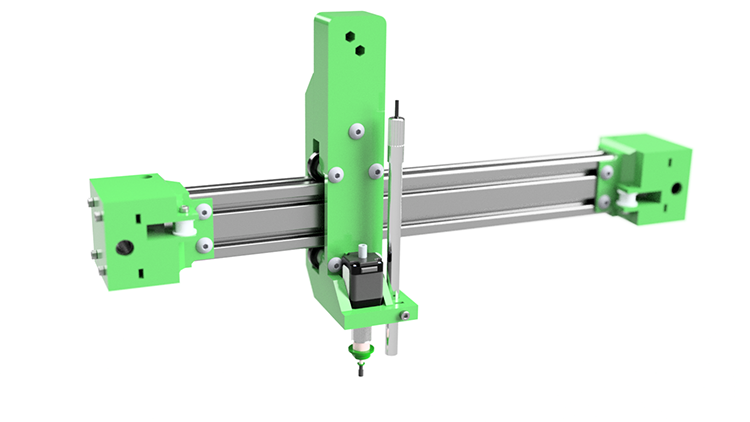

The New Gantry

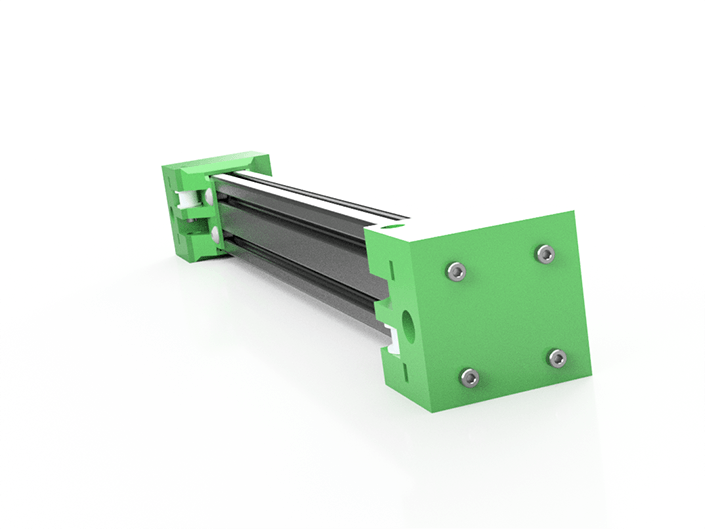

I needed something that was more solid, but didn’t add too much weight to the XY axis. After having talked with a few people, I decided on a 2040 aluminium extrusion profile with V-Wheels on the carriage. The profile won’t bend. Certainly not in the way the aluminum rods did. This was certainly going to be more challenging, because now I need to design new XY joiners, and a new X carriage. I’m not one to back down from a challenge. And let me tell you, Fusion360 can sometimes be challenging… In the sense that on my laptop, it often crashes, and is sometimes very sluggish.

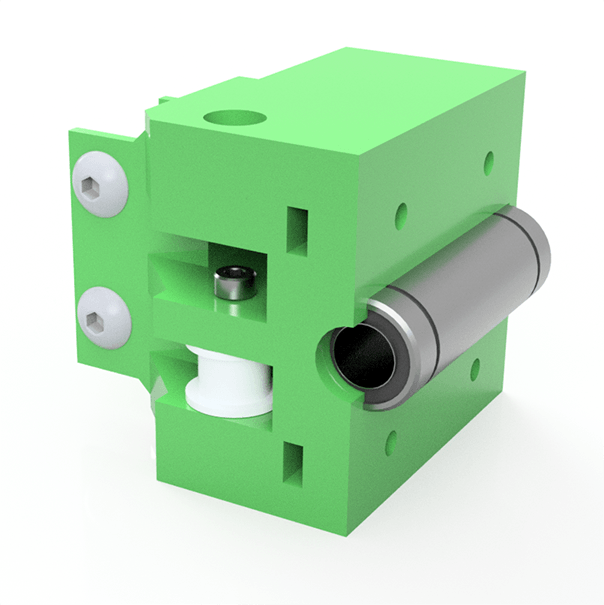

The XY Joiner

Firstly, in order to not have to redesign motor mounts and belt idlers, I’ve kept the belt paths relatively close to the original HyperCube. Naturally not exactly, because now the belts can’t go happily down the middle of the gantry, there’s now a 2040 extrusion profile in the way. I haven’t designed the belts in Fusion360, because at this time, this is not supported. Once I have everything printed and built, I’ll certainly be posting some more pictures of the final setup.

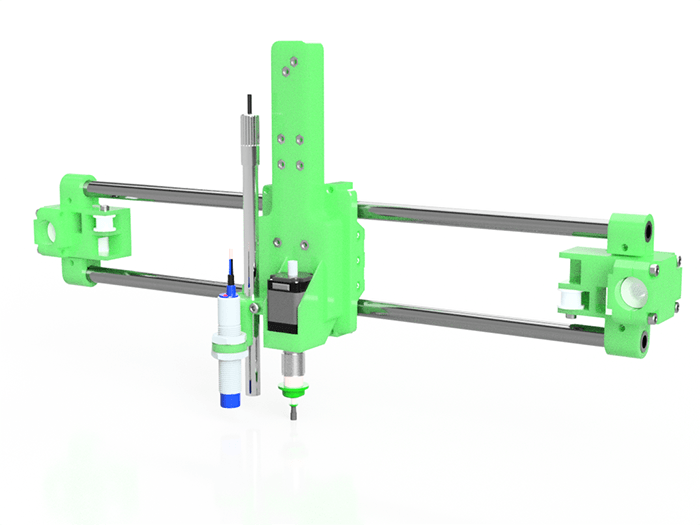

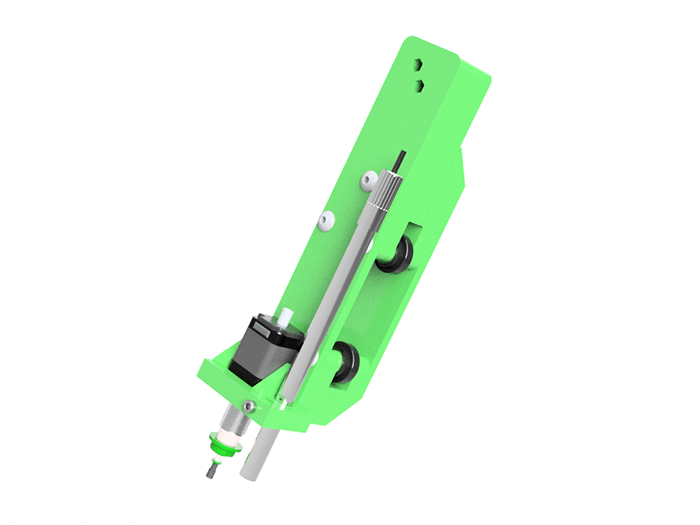

The New Carriage (sort of)

This is essentially a first version of my new X carriage. It’s going in the garbage, and I’ll be completely redesigning it, in the next few weeks, when I can find a bit of time. It uses 4 V-Wheels, two of which will adjustable with eccentric nuts.

Currently, it is two separate pieces (front and back). My next design will be one solid piece of plastic.

It is possible that I spend a bit more time, and try to fix/finish this carriage, but I think it will honestly be easier to just start over on it.

More to come

This is where I’m currently at, and I will be writing more on the progress of the redesign.